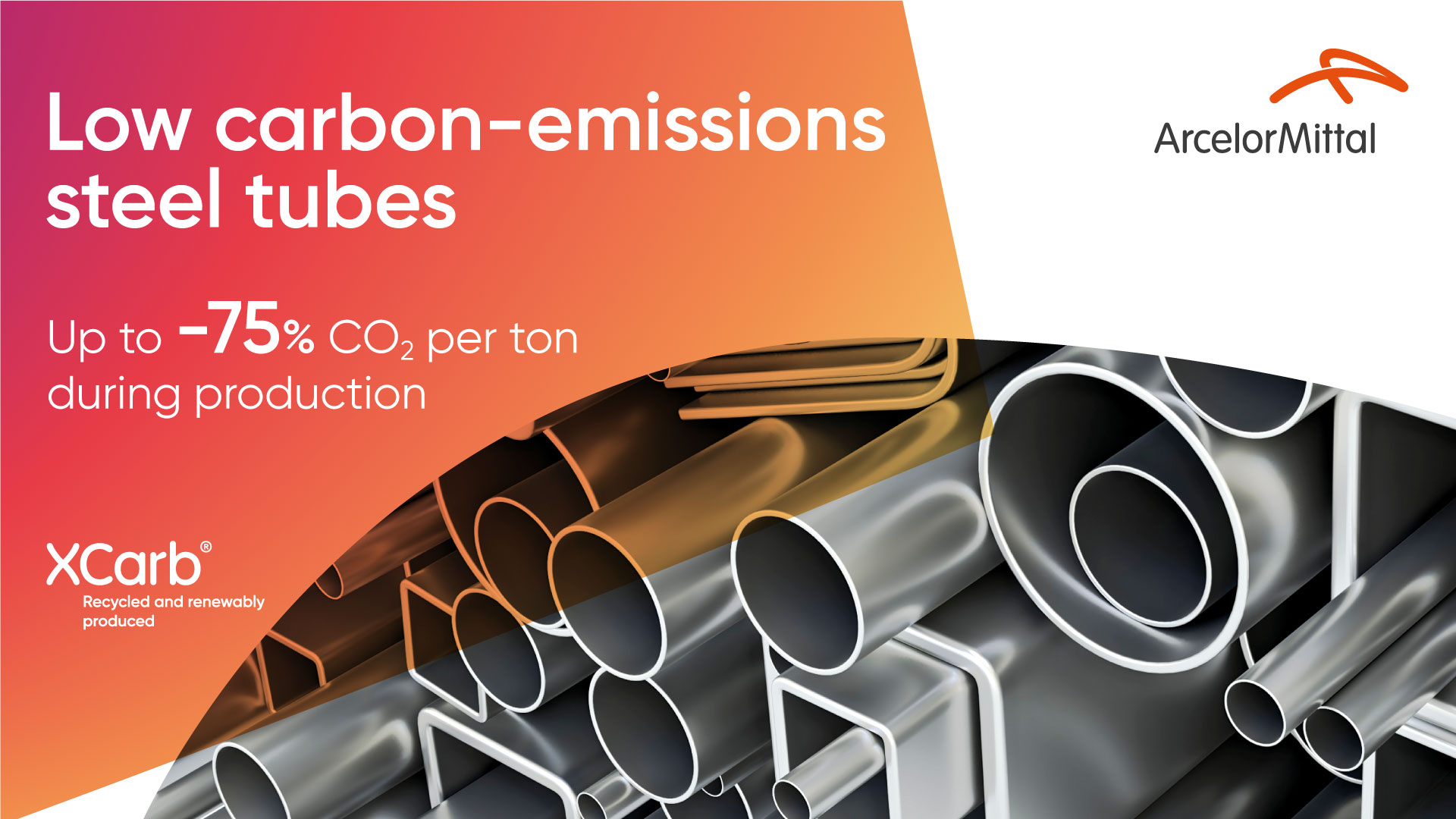

The industry’s first low-carbon emission steel tubes, with a CO2 emissions reduction of up to 75%

ArcelorMittal Europe -Tubular Products has launched a new, low carbon-emissions steel tubes; This new solution, made of XCarb® recycled and renewably produced steel, has up to 75% less CO2 equivalent - one of the highest CO2 emissions reductions rates in the steel tube industry. Using XCarb® recycled and  renewably produced steel tubes allows customers to reduce the global CO2 footprint of their projects, products, and finished goods to meet their own decarbonisation targets and align with the Paris climate goals and the European Green Deal.

renewably produced steel tubes allows customers to reduce the global CO2 footprint of their projects, products, and finished goods to meet their own decarbonisation targets and align with the Paris climate goals and the European Green Deal.

Steel tubes are widely used in various structural applications such as building frames and sprinklers, solar structures, windmills, scaffolding, or machinery. ArcelorMittal Europe -Tubular Products is the largest producer of steel tubes, manufactured at its 15 sites in Europe. stands at the side of its customers to take part in this transformation.

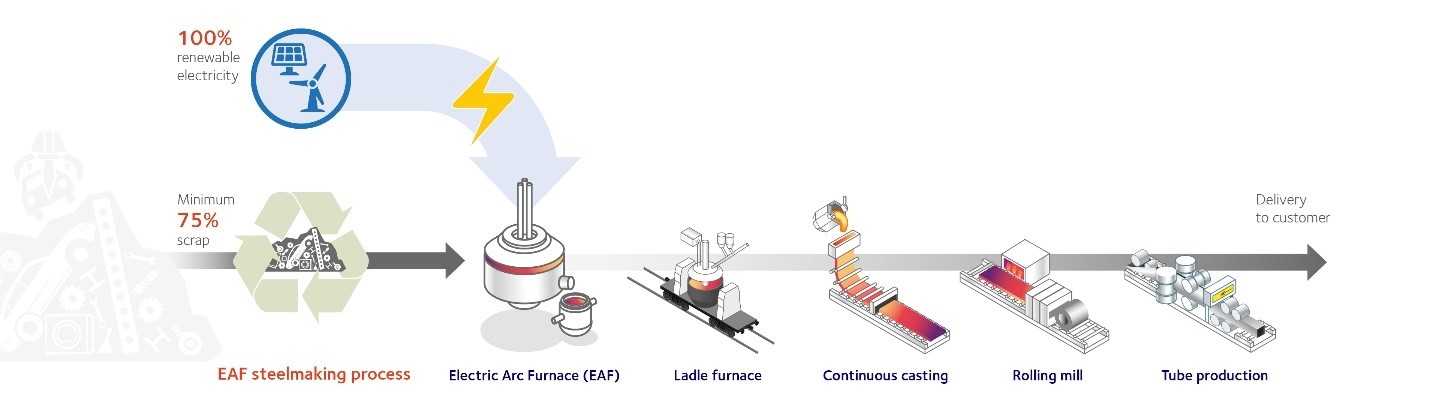

ArcelorMittal Europe – Tubular Products is now able to produce and offer the first low-carbon emissions hollow structural sections using XCarb® recycled and renewably produced steel. This label is applied to steels produced in an electric arc furnace (EAF) using high levels of scrap and 100 percent renewable  electricity. The electricity used comes from renewable sources such as wind and solar and is supplied via a recognised Guarantee of Origin (GoO) scheme.

electricity. The electricity used comes from renewable sources such as wind and solar and is supplied via a recognised Guarantee of Origin (GoO) scheme.

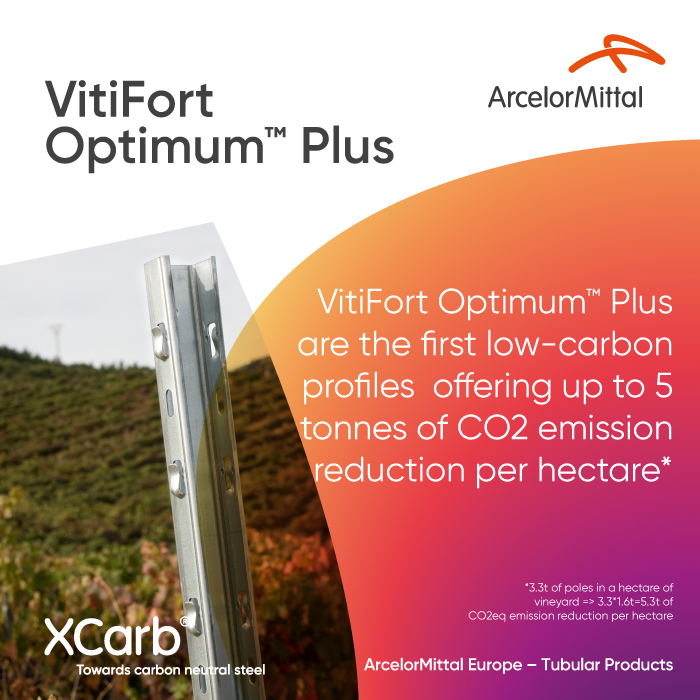

VitiFort Optimum™ Plus, the first range of low-carbon steel profiles for vineyards.

ArcelorMittal Tubular Products presents its latest innovation in the viticulture industry: VitiFort Optimum™ Plus, marketed in France under the brand ALqEOS®, the first range of steel profiles for vineyards using low-carbon steel.

Awarded the Vinitech 2022 Innovation Trophies, VitiFort Optimum™ Plus profiles are made with XCarb® steel produced in the electric furnaces of the ArcelorMittal plant in Sestao, in the Spanish Basque Country, a site that aims to achieve carbon neutrality by 2025. VitiFort Optimum™ Plus profiles are the first low-carbon profiles offering up to 5 tons of CO2 emissions reduction per hectare.

The advantages of the new VitiFort Optimum™ Plus profiles are:

- CO2 footprint of about 900 kg/t (compared to the usual 2.5t of CO2 emitted in Europe to produce one tonne of anti-corrosion coated steel).

- Sendzimir Z-275 zinc coating.

- Optimum" zinc-aluminum magnesium coating technology Magnelis®: excellent corrosion resistance.

XCarb® as a complete and complementary solution for project flexibility

Given the inherent complexity of construction projects, there is no "one size fits all" solution for low-carbon construction materials. This is where XCarb® stands out, as it offers our customers a range of complementary options to meet diverse needs. The experience has shown that our customers prefer a holistic approach concerning the scope 3 carbon emissions of their building materials. For this reason, we offer physical lower-carbon materials, such as Hollow Structural Sections made of XCarb® recycled and renewably produced steel in various dimensions and on demand. Additionally, we can provide all our products with XCarb® Green Steel Certificates, ensuring that we cover the full spectrum of a project's requirements.

At ArcelorMittal Europe – Tubular Products, we offer more sustainable solutions to cover the full spectrum of your project’s requirements, either coupled or decoupled from the physical steel, with XCarb® Recycled and Renewably Produced and XCarb® Green Steel Certificates.

XCarb® Recycled and Renewably Produced (RRP)

- Steel made via the Electric Arc Furnace (EAF) with a minimum 75% of recycled steel and using 100% renewable electricity

- Product offered with a verified Environmental Product Declaration or Life Cycle Assessment

- CO2 savings linked to the physical steel offered

XCarb® Green Steel Certificates (GSC)

- CO2 credits generated, stored and externally verified in a centralized register and allocated to customer orders as certificates

- CO2 savings are decoupled from the physical steel, giving customers sourcing flexibility

- 2.112t CO2 reduction per certificates

About the XCarb® brand:

XCarb® is the umbrella brand that brings together all of ArcelorMittal’s reduced, low and zero-carbon products and steelmaking activities, as well as wider initiatives and green innovation projects. XCarb® serves as demonstrable evidence of our determination and accelerating commitment to achieve carbon neutrality by 2050. We will continue to drive innovation to meet our decarbonisation goals and are committed to leading the industry transition towards carbon neutral steel. We have the scale, resources, technology prowess and ambition required to make a significant impact.